Here is the background, decision process and developments regarding the “Martinez Crossing” of Nash Mill Road over Wallace Creek. The crossing is on Nash Mill Road about one quarter mile from route 128.

- August 13, 2015 “Martinez Crossing” – report by Pacific Watershed Associates; includes all diagrams; 6.9 megabyte pdf 150813_Martinez Design Memorandum – InclAllDiagrams

- Bill Seekins “Plan B Proposal” – a groundwater recharge site plus plan view of “vented ford” relief channel 150911_WSeekins_GroundwaterRecharge

- Text of the PWA report 150811_PacWatershedMemorandum

- The estimated construction budget (these also appear in the full report, above) Numbers for Francois

- PowerPoint by Francois Christen “Update on the Martinez Culvert” August, 2015 prior to Aug 15 annual meeting 150908_FrancoisChristenMartinez Presentation v2

SUGGESTED READINGS:

APPENDIX C: California Board of Forestry and Fire Protection 2013 Road Rules and Technical Addendum No. 5: Guidance on hydrologic disconnection, road drainage, minimization of diversion potential and high risk crossings 14_-_appendix_c_-_california_board_of_forestry_and_fire_protection

Designing watercourses for passing 100 year floods DesigningWatercourseCrossingsForPassageOf100YearFloods

Aug 15, 2015 Discussion at the annual meeting

Section 1

Aug 15, 2015 Colin Hughes of PWA gives a detailed oral explanation of the plan

Colin: I

was contracted by the board to determine a

design plan for the Martinez crossing that

could be permitted by Fish and Wildlife.

Colin: I

was contracted by the board to determine a

design plan for the Martinez crossing that

could be permitted by Fish and Wildlife.

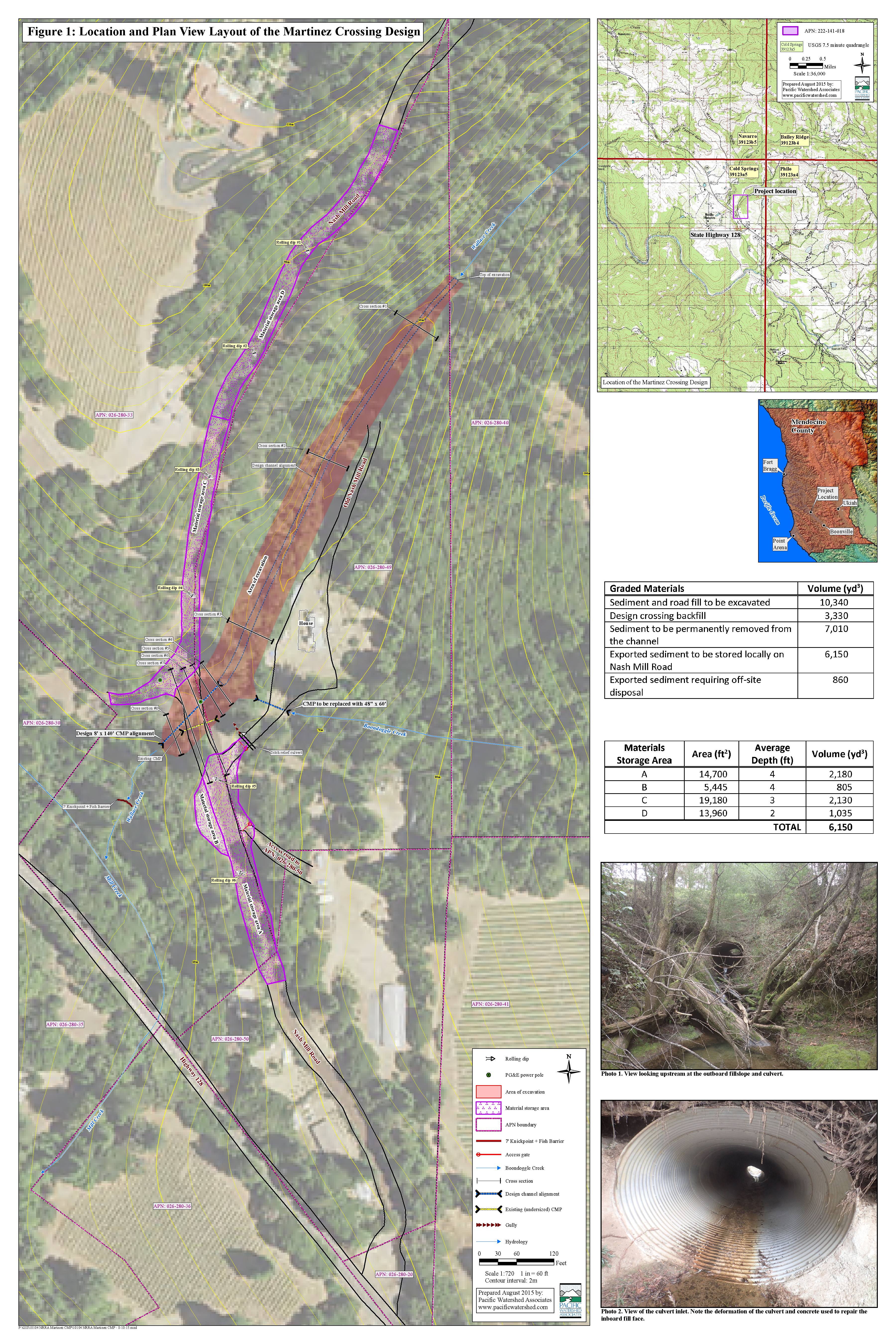

There are actually two properties overlapping the area. Besides Martinez there is Lineck on the downstream end. It’s somewhat of a complicated site.

There are two main risks at the crossing as constituted now.

(1) The crossing was installed prior to the 1950’s. I’ve seen aerial old photos. The crossing contains a lot of organic debris –including logs and material from road construction. This is apparently decomposing and is destabilizing the fill.

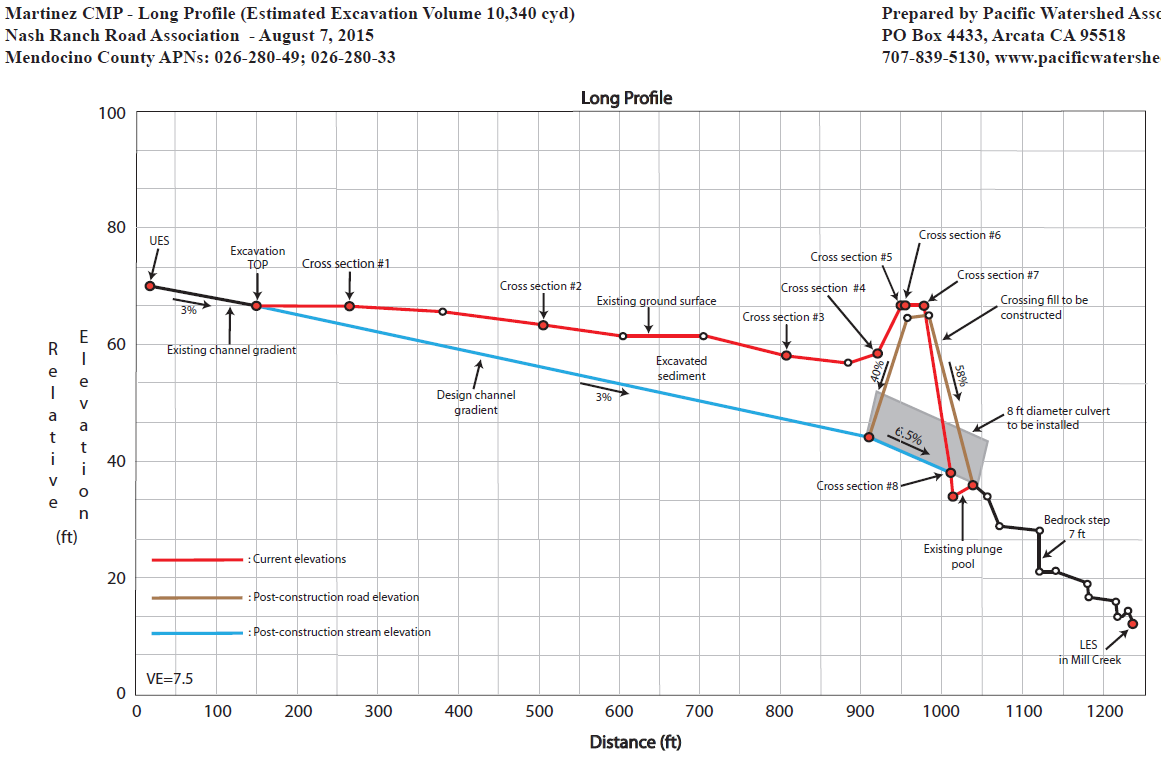

(2) The other main issue is the culvert itself. The culvert is somewhat squashed so its hydraulic capacity is less than that of a circular culvert of that radius. Its hydraulic capacity is far less than what you would provide these days. In a big storm the water could potentially back up and form a big pressure head, flowing over the road eroding the road. If a really big storm you lose a portion of the crossing and hence a portion of the stream-stored fill materials.

The culvert is installed high up in the fill. Nowadays the design standard is to install culverts at the base of the fill. When you install a culvert high up it allows aggregation in the channel, kind of like a pond. That’s what’s happening there. Over 60 odd years you’ve had deposition of channel-mobilized deadload that has built up behind the crossing. Now it’s a large wide flood-plain-looking deposit of channel sediment. It’s like a filled-in pond.

It could be looked at as a groundwater

recharge site, and Bill Seekins has been

adamant about pointing that out. There is

water stored in those channel sediments

that releases over time in the summer.

That being said, the channel is almost a

perennial creek. Water flows nearly year

round. It’s known as “Wallace Creek.”

The creekbed is next to Miriam Martinez’s

home, with all the willows in it.

The approach supported by the agencies – State Water Resources Control Board, Fish and Wildlife – is a channel restoration approach. Normally when they permit projects to replace culverts in streams, that includes the removal of the foreign material because it is a risk in the event of culvert failure. That material stored in the channel can potentially be released. Downstream from that crossing is Mill Creek which is a valued salmon stream.

Miriam: Will the flow be restored to its original position?

Colin: That would be the design goal. The sections I have distributed to you show that. By looking at older aerial photos you can easily tell that was the native alignment. 59:40

As contracted we evaluated what designs are viable. Do we need to follow these protocols which are widely accepted by Fish and Wildlife, or could we go with an engineered approach in order to save some of that floodplain area? We also looked at the cost of installing a bridge. The cost was much greater. That was dismissed because the cost was much greater than even the cost of the larger culvert.

I engaged Fish and Wildlife in the discussion to determine which way. We had Rich Macedo from Fish and Wildlife review the site. He has never seen an “engineering” project of that large magnitude go through the permitting. They were all dismissed. I’m talking about some large engineered rock structure which could retain the stored material in even a large storm context [i.e. turning the crossing into an engineered dam.] He said that’s not likely something that would be permitted. So I’ve gone with the classic methodology of excavating the foreign material and placing the culvert at the bottom of the fill.

Miriam: That means taking all my soil from the creek?

Colin: Along the profile of the channel, yeah.

Roger: This costs less than a couple of bridges?

Colin: Yes. You would probably want a double-lane bridge. We have engineers on staff. We do a couple of bridges a year. [1:02:09] That being said, there’s a seven foot knickpoint in a bedrock step below this crossing so we don’t need to provide for fish passage. In a fish channel – which this isn’t – F&W wants a natural stream channel which pretty much necessitates a bridge or an arch culvert. Since this isn’t a fish channel we’ve specified an 8’ diameter culvert 140’ long.

The current 48” culvert is functioning like a 42” culvert.

Based on our 100 year flow calc, a 7’ culvert is just barely enough. I’ve recommended an 8’ because the cost difference is negligible. For a few more dollars, an 8’ is more tolerant of blockage by debris.

Colin: Here are the risks of not going ahead. The culvert fill is compromised. Even when you don’t see surface flow you can see water seeping beneath the pipe. There have been past attempts by local landowners to apply plastic to limit infiltration. In the culvert itself, the fill slumped and sheared the culvert incredibly. In Francois’s picture you can see some of that. There was an attempt to install uncured concrete in the culvert separation.

Bill: The patch was

cured concrete and it was applied 25 years

go. It’s held for 25 years and not

shifted.

Fred: Looking into your crystal ball, considering that this is supposed to be an El Nino year, how fragile do you think it is?

Colin: There’s no

formulaic way to determine risk. I’ve seen

these things over the years. The fill

being compromised in my mind is the

primary driver for replacement. The

culvert capacity could probably pass the

10 year storm. But it would not

necessarily require the magnitude of the

100 year storm to cause failure. Over time

the organic material degrades. This allows

“preferential flow paths” – macropores and

soil-piping – through these fills. That’s

happening at our crossing right now.

There’s erosion occurring with the fill

over time. I’ve seen these types of

crossing undergo massive settling from

erosion within the crossing. Then

everything collapses inward. It’s hard to

predict how rapidly that would occur. But

it’s obvious that has occurred in the

past. Those are the primary issues with

that crossing. 1:08:03

Bruce: To cast some doubt about the odds – on 1/1//2006 we had what was calculated to be the “75 year storm”. This determination was by Fish and Wildlife’s people – a colleague of Linda Macawee. I own a quarter mile of Mill Creek. That flood knocked down every [alder] tree in the Mill Creek ravine and completely changed the cross section of the creek at several points. No other event in 15 years has begun to touch the effect of that one day. But I understand the Martinez culvert held. It didn’t even settle.

Miriam: It did just fine. I keep that channel clear of all trees and debris. I spend a lot of money on that. I also have the fence posts [.i.e., “trash racks”] that prevent any logs from floating down to block the culvert. So I’m always cleared.

Not to mention – the road is in the position it’s always been, and has never flooded out.

Colin: The volume of material I compute we’d be excavating we’ll locally store, on Nash Mill Road by building up Nash Mill and out-sloping it.

Colin: We would remove the channel-source sediments that provide Miriam’s in-channel aquifer.

Colin: I’ve included costs for the re-establishment of domestic water infrastructure. We plan to capture water upstream.

Miriam: Roederer pumps

that; they have water rights. You won’t be

able to get that. I have secondary rights

to them. It’s in my deed.

Fred: How “fragile” is it? If the crossing fails the entire ranch would be cut off.

Colin: Using the established methodology for estimating sediment risk we estimate the quantity of material that would fall into the creek. (explains the technical methodology.) We compute that in that event, 8,800 cubic yards of material would fall into the creek.

I’ll go into the details of the design.

Fred: The cost?

Colin: $436,000.

Don: Before everybody dies of a heart attack, remember that it’s something for which we would get grants. We’re not going to do special assessments or something like that. [1:16:10]

Colin: The two major risks are: (1) what if it fails? In that event the Road Association would have to pay for repairs. A preemptive approach will allow you to reduce the risk, to get grant funding.

Fred: Does your organization offer counsel on funding?

Colin: Generally these grants need to be pursued by non-profits. We work on 50 or more projects a year.

Roger: How many years will we get out of this new culvert?

Colin: We propose an aluminized galvanized steel culvert. The design life is 30-50 years.

Roger: Did you consider and price a concrete culvert?

Colin: No.

Colin: (walks through the costs, listed on a handout we all received.) Major costs are excavation, removal, placement of sediment as close as possible; out sloping of the road. Replacement of the culvert entails digging all the way down to base; placing the culvert.

Colin: Incidentals include moving two PG&E power poles. We contacted PG&E for a figure for this. We used a figure of $50,000.

Colin: The permitting process I outlined is through a coordinated grant/permitting process. If the various permits were sought separately I estimate costs of $40,000. By this combined approach the permitting cost is much less.

Bill: How would you mitigate the loss of the water? The water that goes underground and percolates out is a good source of cold water to Mill Creek. Last summer Mill Creek dried up a quarter mile upstream. Blue Meadow Farm had to buy water and have it trucked in. The Martinez floodplain leakage was the only source.

Colin: I don’t have designs for mitigating for that, but the view of F&W is that the channel-stored sediment should be removed. 1:21:33

Zach: How to preserve vehicular access during the work?

Colin: Awkward. As we begin to excavate we could lower the crossing a lot, allowing continued access along the alignment of Nash Mill. But once we work with the crossing fill itself to put in the culvert, we’d have to place ramps that enable a wild turn, upstream and then back out again onto the shoulder.

Nancy Mayer: On Miriam’s property?

Colin: Yes.

Colin: This is a summer job; it would not be allowed in winter. Clear water diversion is always a significant cost to these jobs. You need a clear water diversion above the site that conveys clear water from Wallace Creek all the way past the worksite and back into the channel below. You would have extremely turbid waters coming out of the construction site as you excavate. This would need to be pumped to flat areas so the sediment would be dropped into the ground without reaching downstream channels.

Miriam: That’s probably my front yard – that flat area.

Colin: We would have to utilize many different areas of your and the other properties.

Colin: There are a lot of alternatives. The engineered alternative I mentioned earlier I brought up to F&W. They said it probably never would be permitted. If there were a continued risk of failure they would want to know what it is. Design plan $45,000 – $50,000 just for a plan for that type of treatment. So I did not pursue that.

Colin: Continuing with the costs… the PG&E component I mentioned. Water infrastructure needs to be changed; costs are in there. Another undersize culvert is on Boondoggle creek. It has to be addressed. Otherwise you would have a shotgun culvert feeding into this stream.

Fred: A bridge is not viable? It’s more than $400,000?

Colin: The materials alone – a bridge perhaps 19’ wide, 40’ long – is about $75,000.

Doug: The Mill Creek bridge was $60,000. But that’s an old cost – around 2001.

Colin: What I have designed is based on tape and clinometer surveys, laser rangefinder surveys. Though I provided my design plan with profiles and cross sections it assumes a shape morphology of channel beneath the sediment – guesses. This is a natural channel restoration attempt. So an expert knowledgeable in exhumation of channels would have to be engaged by permitting agencies to confirm the channel location. If a slight meader or change in the alignment in the channel were uncovered, that would have to be followed.

Nancy Mayer: So there are a lot of unknowns.

Colin: There’s not a lot. It’s typical. But there’s on-the-ground evaluation that will be required. 1:28:07

Colin: There’s a really significant re-vegetation component. We called for riparian vegetation, conifers, redwoods. We allowed for labor.

Miriam: One of my main concerns with the alignment is my main cistern. It’s right there. That’s vital to my survival on my property. If you reroute the stream, what will you do about my cistern?

Colin: Replace it , with a water source that would be upstream, some spring box type of channel that feeds to – I budgeted for – 5000 gallon water storage capacity.

Miriam: It’s currently much bigger than that.

Colin: There’s ample costs in the design plan for domestic water infrastructure.

Colin: We also budgeted for re-rocking Nash Mill Road and drainage, all the effects there. Some soil will be stored on the Lineck property, most on Martinez. And there’s a Ruffler property that’s a bit east that would have minor impact.

Steve: Is there a compromise opportunity other than complete excavation, leaving some sort of dam so that her water is not impacted so much – some opportunity to solve both things?

Colin: Two things: (1) The culvert needs to be totally excavated and replaced. Existing fill needs to be totally excavated. It’s compromised. (2) You’d have to retain that wall somehow, to build like a dam face. I was told, F&W (Fish and Wildlife) will not permit that and you’d have to pay design costs for something that is unlikely to be allowed.

Fred: Can you tell how long it’s taken for all this to accumulate?

Colin: It looked really aggraded in 1952. That’s when timber harvest ended. There was a lot of debris.

(Colin concludes; audience applause.)

Section 2

Bill:

(takes the floor) According to the

contract with Pacific Watershed, PWA has

no liability for groundwater variations.

NRRA assumes that liability. By lowering

the creek you lower the groundwater. The

creek is the elevation of the top of the

water table by definition. The water soaks

down to the water table. Lowering the

water table in the creek will lower it for

all the surrounding hills also, 30-40 ‘

from the creek. 1:36:01

Bill:

(takes the floor) According to the

contract with Pacific Watershed, PWA has

no liability for groundwater variations.

NRRA assumes that liability. By lowering

the creek you lower the groundwater. The

creek is the elevation of the top of the

water table by definition. The water soaks

down to the water table. Lowering the

water table in the creek will lower it for

all the surrounding hills also, 30-40 ‘

from the creek. 1:36:01

I took three sediment samples. I dried them, then tested how much water they would hold. I determined that the sediments can hold 63-75.5 gallons per cubic yard. I round that to 70 gals per cubic yard. The flood plain is roughly 670’long and 20-60’ wide. I estimated the volume of the upper 3’ flood plain sediment at 3226 cu. yd. I multiplied that by the capacity I had determined. So the top 3’ of the flood plain holds 226,800 gallons. The flood plain goes down 12’ in a lot of places, so I estimate an average depth of 6’. I got a figure of half a million gallons of water. Probably a million gallons is closer but I can’t claim that.

This water leaks slowly through the fill. This produces cold water which leaks into lower Mill Creek. As I mentioned, last year at Blue Meadow Farms in Holmes Ranch the creek dried up but Martinez spring was still putting out water.

My proposal is to do a flood relief channel on Nash Mill Road so if it plugs up the water doesn’t run across the fill and wash out the road. By doing this you’d have a relief area for a 100 year flood. Miriam has volunteered for this low point to be her driveway. You have a gentle swale of maybe 100’ width, depth about 1’, so the flood waters run around to the parking lot between the parking area and the redwood trees – which are notorious for holding the soils together even on steep slopes. 1:38:12

You may have noticed the sign I put up at the big Horseshoe Curve just before Clowe Ridge; it reads “flood relief channel”; When was that channel put in?

Doug: It was part of the grant, fourteen years ago.

Bill: That was to protect the road in case the culvert backed up. Doug will tell you, he pulled a catfish out of the debris that plugged the culvert. [laugher] It was from Peterman’s pond.

If you stand at that sign and look down the hill, you’ll see there’s minimal damage to that hill. If it had eroded the fill the fill would have been taken out in a very short time.

Right now there’s an apron in place leading water into the culvert. It’s concrete up to a point, extended with plastic. My plan B is to extend the apron farther upstream, and to implement this flood relief channel, until we have money and agreement of the landowners in the area.

I’m not an engineer, I’m a geologist. My masters is in groundwater geology.

Zach: Are you proposing to use the current culvert indefinitely?

Bill: No, not indefinitely. The current one was put in in ’70. This is buying time. This requires no permits. We could do it right now.

Colin: That structure is a critical dip. That’s an excellent failsafe until a major remedy is possible. There IS a grading ordinance, but you would not need it for this project.

Miriam: The dirt scraped off to do that could be used to shore up the down-side hillside, to cancel some of the gradual erosion.

Bill: You can see, the material removed can be piled along here, to raise the level of the downhill side. There’s a place over the existing pipe where you could embed in a log parallel to the road, along the side so vehicles could not go over the edge. This would also raise that edge by a foot or so.

Nancy Mayer: Cost?

Bill: Just some grading. Negligible. Maybe $1000.

Steve: It’s a postponement, not a permanent fix.

Bill: It might buy a lot of time.

Steve: In the event of the culvert being blocked, this prevents the road from being washed out?

Bill: That’s exactly right. Those of us who saw the Flower Patch damage due to those culverts plugging, saw how water had removed many yards of fill in a very short time.

This is just an escape channel.

Redwood roots like those that are decades established in the crossing are really good at holding soil.

Everyone please stop at that sign “flood relief channel”, look down the hill and see the small amount of damage which could have been much greater without the relief of the channel.

Fred: Where does this drainage go after the dip?

Bill: It just runs around and goes back down into the drainage leading to Mill Creek.

Nancy Mayer: How about a ballpark figure?

Bill: Just some backhoe hours. Maybe several hundred dollars.

Miriam: It would probably be a couple thousand.